High speed machining for aerospace applications

The metal cutting industry continues to develop in order to meet the advanced requirements of the various industrial applications. High speed machining meets the demands of industries which are required to produce high quality tools. These industries include the car manufacturing industry, space and aviation industries, and medical industry.

Using high speed machining offers several major advantages which increase the tools quality, lengthen tool life and reduce cycle times. These advantages enable the achievement of the best, most advanced tool manufacturing.

Challenges when using traditional machining process:

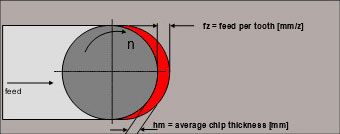

The need to remove large volume of raw material or the need to perform deep and full slotting, forces its users to use roughers with profiles which are able to split the chip length to small, more easily removed chips at depth of 1XD -MAX. The traditional application forces the company to work with relatively low machining conditions and therefore causes varying and heavy loads on the spindle, resulting in poor repeatability of slot width. See drawing below.

Furthermore, surface quality is not even, a factor that forces users to further use other tools (finishing tools) for the final finish of the product. In addition, end mill wear is relatively high (short tool life) and cycle time is long.

In order to perform deep and full slotting, as shown in the drawing above, the company can use an endmill which is narrower than the slot width, such as multi flute Varimill III. This enables high feed rate, maximum depth of 2xD-5xD, small and unified chips. It includes software which allows chip control and enables users to work at relatively high machining conditions, spindle feed speed (rpm) and feed rate.

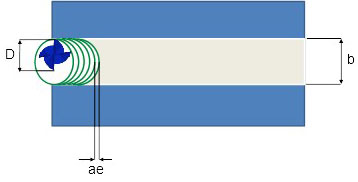

The drawing below presents the work route and the climb machining direction on the raw material. It also shows that during the high speed machining process, the application is not in full width but with small stepover.

When using designated high speed machining, such as VARIMILL - III which is geometrically adjusted for these applications, it is possible to work at relatively high speed, high feed rate, maximum chip depth and unified, narrow chip width (between 10-15% of tool diameter).

In order to gain full control over chip width during machining and through the length of the tool path, the company has to use software designed for this purpose. In this way, the company makes sure the chips are quickly evacuated and do not accumulate in the work area. Furthermore, the loads on the spindle remains even, resulting in unified tool wear and relatively lower load on the tool.

The above is applicable on various raw materials: Steel, hardened steel, stainless steels, exotic materials like Inconel and Titanium. Suitable applications and machining processes have to match each material requirements.

The main advantages of using high speed machining are:

- Substantial increase of spindle feed (RPM) speed and feed rate

- Ability to machine at maximum depth while controlling small and unified chip width

- Elimination of sharp machine moves

- Even distribution of loads

- High quality surface

- Substantial reduction in cycle time (Material Removal Rate)

In order to implement the high speed machining technology:

- Fast machines adjusted to the technology

- Designated tools, geometrically adjusted to the high speed machining technology

- Software which enables full control of machine and tool load with full control of chip width through the machining process.